OGC February Highlights

As we wrap up a very busy and exciting February, we’re excited to share one of the biggest game changing developments in our history, as we unveil what we have been working on over recent months. It’s in our DNA at OGC, to push the boundaries of innovation, precision, quality, accuracy and customer satisfaction. February marks a significant milestone in our efforts on this journey.

Unveiling Our New Custom Built Wire EDM Facility:

For those who have been following our teaser updates, the time has finally come! We are thrilled to officially unveil our brand-new Wire EDM facility, marking a major leap forward in our manufacturing capabilities.

After months of research, development trials, compiling investment cases, training and pure hard graft, our vision has now become a reality. This space represents a huge leap forward in our commitment to precision and innovation in gauge and component manufacturing to further support our customers with highly accurate spline gauges delivered at pace to industry-leading lead times.

We’re excited to share this journey with you—watch our grand reveal video on LinkedIn to see the facility in action:

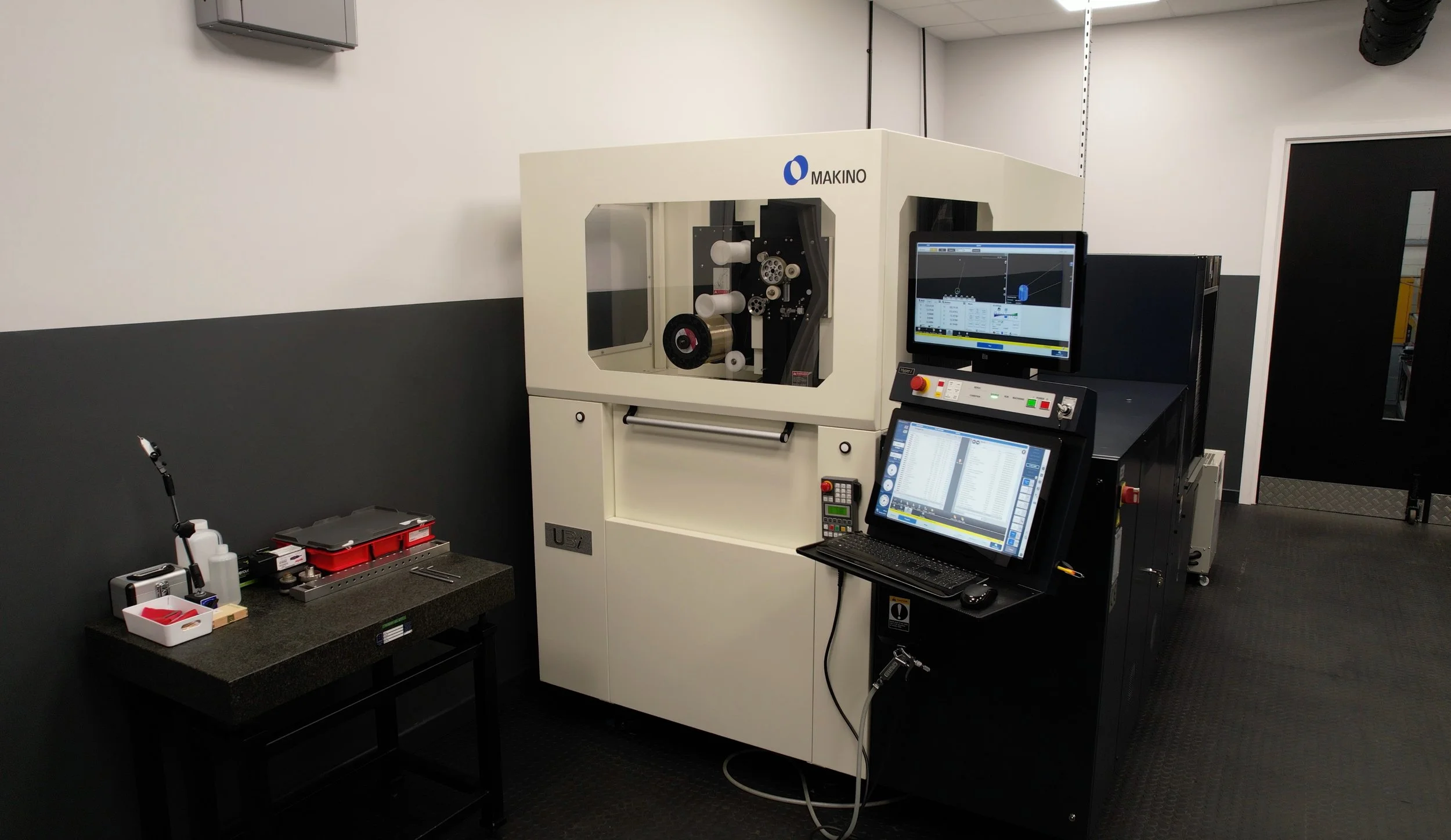

Delivery of new Makino Machine from NCMT:

One of the biggest investments in our new facility is our new Makino U3i wire EDM machine. The result of detailed trials and thorough examination of a machines accuracy and repeatability led to NCMT and Makino being selected for our investment. Huge thank you to the NCMT team for their incredible engineering, service, and support in delivering a transformative process. Another big thank you to the team at CTC Europe, who delivered the machine with such care and attention to detail. The Makino U3i wire EDM machine is the cornerstone of our new facility, fundamental in a game-changing capability to deliver even more precise components, faster lead times for our customers to even tighter tolerances than industry norms.

What our New Facility means for our Customers:

Unmatched Precision – Wire EDM technology enables ultra-fine tolerances, making it ideal for intricate spline gauges and spur master gear gauges and components with complex geometries.

Faster Turnarounds – Our investment in this cutting-edge custom built facility supports industry-leading lead times, delivering you project timeframe advantage, security of supply and peace of mind.

Hard Metals - Wire EDM (Electro Discharge Machining) knows no bounds with regards to material hardness. Whilst pre-blank manufacture has to consider the material processing capabilities carefully, the EDM process will tackle the hardest to machine materials including: tungsten, high-alloy steels, stainless steel, Inconel, molybdenum, and most superalloys; essentially, any conductive metal.

Expanded Capabilities – With our Advanced Custom Wire EDM Facility, we now offer the market a component production capability, delivering unrivalled accuracy for intricate, high-specification components. Customers can explore the advantage this brings in design flexibility, enhanced quality and accuracy.

To find out more about our new capabilities, Ryan explain more here:

A Special Visit from Tony Finn – Strengthening Expertise and Innovation:

This month, we had the pleasure of welcoming Tony Finn, a key member of our senior management team, to OGC. Tony took the opportunity to explore our brand-new Wire EDM setup, and his insights were invaluable.

During his visit, Tony was particularly impressed with the precision and capabilities of our new Makino machine. His expertise in the field allowed him to provide valuable feedback on how this investment further strengthens our ability to deliver high-accuracy, high-quality gauges and components at pace.

Beyond the technical discussions, Tony’s visit was also a fantastic opportunity for knowledge sharing and mentorship. He spent time working closely with the team, particularly Ryan, offering guidance and support as we continue to push the boundaries of what’s possible with our new venture.

First EDM spline gauge order from our New Facility:

February marked a major achievement for OGC as we successfully completed our very first order from our brand-new Wire EDM facility!

This order was a spline ring gauge and was manufactured in just 48 hours, demonstrating the speed and efficiency that our investment in this cutting-edge technology has unlocked. This achievement is a testament to our vision, team work, relentless pursuit of advancements and pure hard work that went into setting up the facility, training, and launching our state-of-the-art machinery.

To celebrate this milestone and recognise the efforts of everyone involved, we took a moment to thank the team for their dedication and commitment. A special shoutout goes to Ryan, who led the team in learning about the new machinery and refining our processes, ensuring we continue to push the boundaries of precision engineering.

This is just the beginning! With our Wire EDM facility now fully operational, we’re excited to continue delivering highly precise, complex gauges and components with industry-leading quality and turnaround times.

Continuous Improvements from OGC:

Throughout February, we made further upgrades to our facility, including new flooring in the office, which Clive, our General Manager, came in on a Sunday to lay. In addition, we’ve implemented a new flooring layout in our main factory, designed to enhance efficiency, safety, and workflow. These improvements are part of our ongoing commitment to maintaining a high-quality working environment that supports both our team and our precision engineering operations.

February has been a landmark month for OGC with the official launch of our Wire EDM facility. These advancements mark an exciting step forward in our commitment to precision, efficiency, and innovation. We look forward to sharing more over the next few months.