OGC June Highlights

As we passed the halfway mark of 2025, June brought new Milestones and another wave of progress across all areas of OGC. With continued growth, exciting customer projects, and developments both in-house and across the industry, it’s been a month defined by momentum and focus and we are excited to share what we have been up to in this months newsletter.

UKAS Accreditation Secured for Spline Gauges & Master Gears:

We’re proud to share a major milestone at Original Gauge Company: We have received official notification from UKAS that our application for an extension to scope of our Schedule of Accreditation for the measurement and calibration of Spline Gauges and Master Gears has been granted.

This accreditation is hugely significant for our business, team, customers and the high precision advanced engineering sectors at large, who have been craving the need for additional metrology capacity in this very niche but critical area of measurement capability. This success comes after months of preparation, process, procedural development, staff training and simulations. The success, a culmination of efforts to support a rigorous UKAS audit, now positions OGC as the UK's only laboratory with a UKAS schedule covering a breath of scope for: Ring & Plug Type in thread/screw gauges, plain gauges, taper gauges, Rok-it gauges, spline gauges and master gears.

This significant achievement for our team, whose expertise and commitment to excellence pushed the boundaries of precision measurement within gauge engineering. Special thanks to our formidable team: Sam Payne, Jacqulin Sagurs, Ryan Nash, Clive Legg, Tony Finn and consultant Michael Searl, who's collective team efforts, dedication, drive, skill and determination made this possible.

Most importantly, for our amazing customers, we are delighted to now provide you solutions for Spline Gauge & Master Gear manufacturing and re-calibration with UKAS certification release to the ISO-IEC 17025:2017 standard of accreditation. We look forward to welcoming new customers from across the globe, who rightly demand this highest level of accreditation, providing peace-of-mind through the World's most highly respected accreditation body and accredited companies.

OGC now stand at the forefront of British Gauge manufacturing in a unique position as the UK's only gauge manufacturer with in-house spline gauge, master gear and thread gauge manufacturing capability and combined UKAS schedule of accreditation for measurement across this full scope of gauge disciplines.

One of the most powerful endorsements came from the UKAS auditor, who described the OGC team as “truly exceptional”, praising their enthusiasm, open-mindedness, and depth of knowledge.

This accreditation is more than a technical credential; it reflects the passion, pride, and standards that define everything we do.

Thank you to our customers and partners for your continued support as we continue to lead the way in calibration excellence and metrology innovation

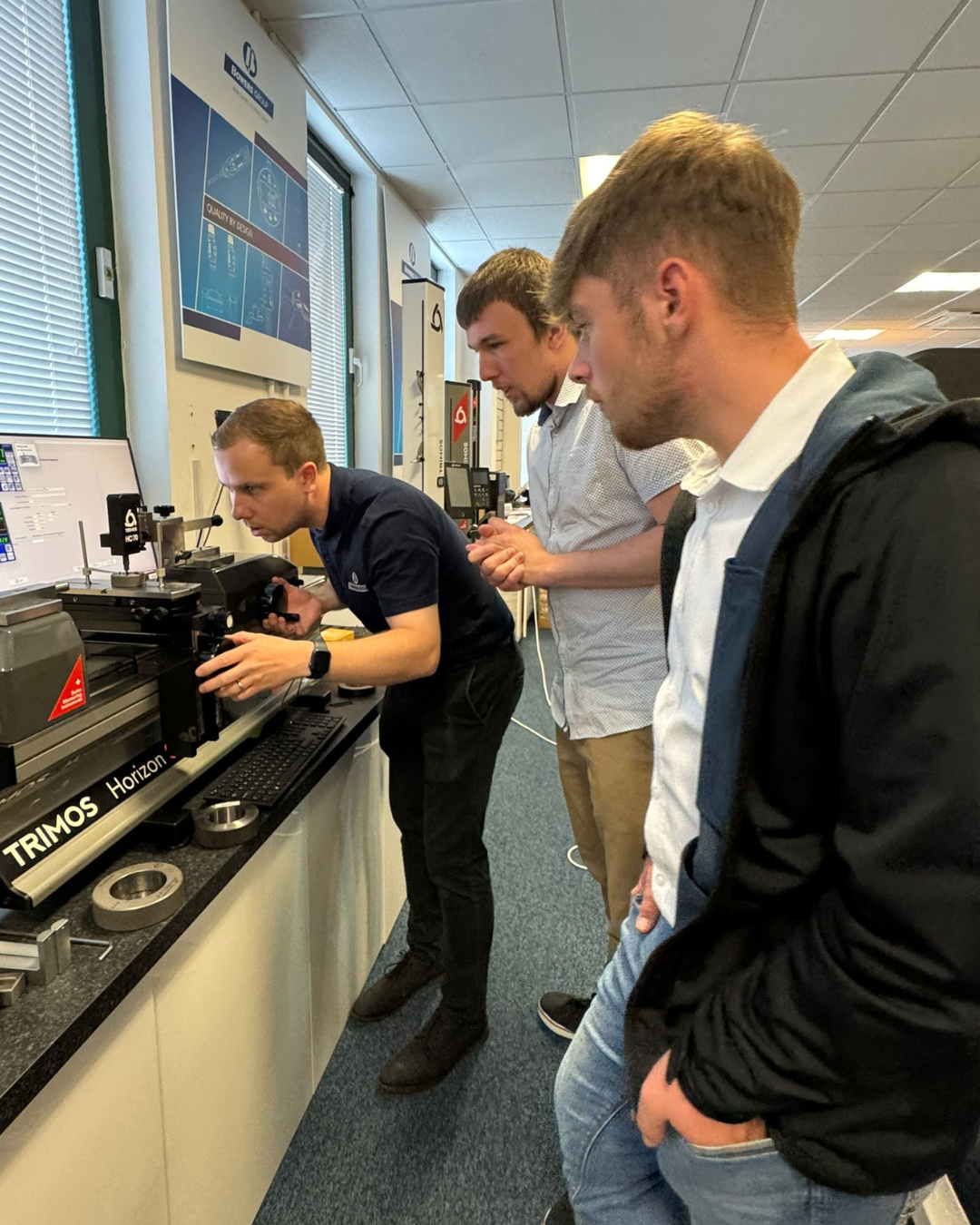

Strengthening Our Metrology Roadmap – Visit to Bowers Metrology:

We kicked off June with a focused technical visit to Bowers Metrology, a respected name in the industry for high-quality measurement solutions and trusted UK sales support. Bowers represents some of the world’s leading metrology brands, including Sylvac, Trimos, Baty, and their own Bowers equipment range.

This visit formed part of our ongoing review of advanced metrology technologies, helping to shape and strengthen the technical roadmap that underpins OGC’s continued evolution. As we invest in the future of precision engineering, partnerships like these ensure we stay aligned with the very best in global measurement innovation.

Subcon 2025 & Smart Manufacturing “The Manufacturer” Shows at the NEC:

Mid-June saw the OGC team attend the Subcon Show at the NEC in Birmingham, a fantastic opportunity to connect with some of the UK’s leading sub-contractors, including DP Engineering and others across the precision manufacturing space.

Smart Manufacturing Show, sitting alongside Subcon, was well positioned, providing valuable insights to cutting-edge and in some cases disruptive technologies. Standout takeaways for us were the rapid use of AI in ERP/MRP systems, material, inventory control and factory digital / diagnostics. One particularly relevant area for OGC being the rapid growth and development in global UAV (Unmanned Aerial Vehicle) manufacturing. With component and metrology demands in the UAV sector exponentially increasing, OGC is already engaged in key projects, and we expect this to grow significantly as innovation in this space continues, and so do our high precision, innovative skills align to the demands.

It was an insightful and energising visit that reaffirmed the growing need for innovation, precision, speed, and scalability within key manufacturing sectors.

Delivery at Pace – Leading the Way in Spline Gauge Turnarounds:

June brought further outstanding delivery success across our Spline Gauge production, once again proving OGC’s ability to deliver with unmatched speed and reliability.

As evidenced by these purchase orders placed 5th June for a 25th June Delivery commitment and despatch delivery note 12th June - Just 7 days PO to Completion of 4off spline ring gauges…..Walking the Talk - Exceeding Customers Expectations.

Just one of multiple outstanding order performances, isn’t just a reflection of our cutting-edge technology; it’s a result of the mindset, systems, and dedication that define how we execute.

First Live Master Gear Order Completed:

June marked another exciting milestone for OGC as we successfully completed and shipped our first live production Master Gear orders for:

35T 1MOD 19° PA Full Form

Z68 48dP 20° PA DIN 4, 230-327

Purchase order to despatch in just 7 working days.

These Master Gear articles are exceptional in every respect, with ultra-precise lead and profile accuracy, and surface finishes that are unrivalled in the industry. It’s a proud reflection of our investment in advanced processes, our team’s expertise, and the relentless pursuit of quality that defines everything we do.

Looking for high-precision Master Gears with industry-leading turnaround times? Click below to request a quote or discuss your requirements with our team.

Spline Projects for High-Performance Racing:

We rounded off June with two high-impact spline gauge projects for customers in the elite racing world, one on the water and one on the track. While we can’t reveal all the details, we’ll just say both were powered by Green Energy and driven by innovation.

In true OGC style, our team rose to the challenge, racing gauges through production with precision and speed that left our customers genuinely stunned. The response? Absolute satisfaction, with both clients praising the performance, turnaround, and quality of our service.

Record Sales & Reduced Lead Times:

June delivered strong results across the board for OGC. We recorded our highest sales output and order intake of the calendar year—a clear sign that our investments in capability, speed, and service are paying off.

On the production side, we made major progress in Thread Gauge manufacturing, successfully reducing arrears to their lowest levels in recent months. This achievement directly translates into shorter lead times for our customers heading into July and August.

With momentum firmly behind us, we’re well-positioned to keep delivering excellence at pace right when our customers need it most.